Home > PRODUCT > Accessories > CM- 9060 : Heat transfer compound

- PRODUCT

- Accessories

-

- CM- 9060 : Heat transfer compound

- Storage and Handling

- Store at room temperature above 5℃ have a shelf life of 90 days. Below 5℃ to extend shelf life to one year.

- Surface Preparation

- Surface areas where heat transfer compound (CM-9060) is to be installed must be clean in order to provide a good thermal connection with the substrate. Contact surfaces should be free of oil, grease, dirt, rust, scale, mill varnish and other contaminants. Follow all safety precautions when using any surface cleaning material and method.

- Precautionary and cleanup measures

-

Wearing gloves and safety glasses is recommended.

It should be kept away from eyes.

Waterless soap may be used to remove compounds from hands, arms, etc.

When using CM-9060 heat transfer compound, it should be cleaned using approved solvents, emulsions or cleaning compounds. Toluene will clean up these materials but make sure they are approved for the workplace before using and follow all safety precautions. - Installation

- - A. Installation on valves, flanges, elbow, etc..

-

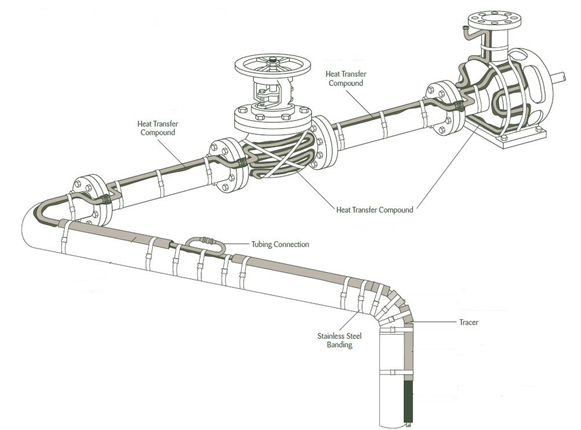

- Install tube tracers in accordance with below picture A. Pressure test tracing for leaks with steam pressure equal to the normal operating pressure or with suitable hydrostatic tests. Repair any leaks and retest until the tracing system is free of leaks. CM-9060 heat transfer compounds are often used where moist and corrosive environments exist. These materials may be applied as a fillet along each side of the tracer as shown picture A. Heat transfer compound is not generally applied over the top of flange. It should be completely embedded on the right spot. All voids between the tracer and the contact surface should be filled to ensure maximum heat transfer. The curing period should be at least 24 hours. Insulate and weatherproof equipment.

- Picture A

- - B. Installation on straight run piping

-

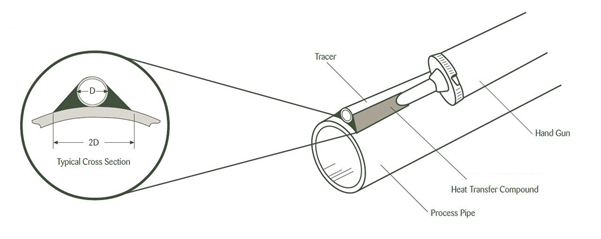

- Install tracers as shown below picture B. Pressure test tracing for leak with steam pressure equal to the normal operating pressure or with suitable hydrostatic tests. Repair any leaks and retest until the tracing system is free of leaks. Tracer may be temporarily positioned on the piping using fixing tape or stainless steel tie wire every 0.6 to 1.2 meter. Prior to installing compound, secure the tracer to the pipe on 60cm center using stainless steel banding and crimp seal for 3/8” or 1/2” O.D. tracers. The bands should be as tight as possible without denting or flattening the tracer. Apply fillet of compound along sides of the tracer as shown on picture B below. Insulate and weatherproof equipment.

- Picture B

- Note

- basically, heat transfer compound is not soluble in water. However, which is not insulated should be temporarily protected from the erosive action of rain or moisture during the curing period.

-

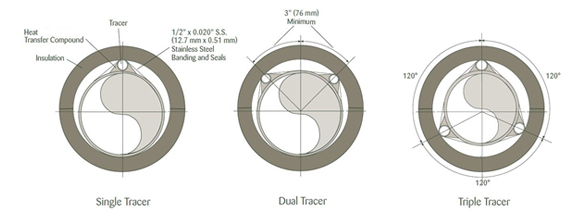

- Picture C